In the realm of workplace safety, a persistent threat looms large – the risk of work injuries involving poor equipment. Each day, workers across various industries face the potential danger of inadequate machinery and tools that can lead to serious harm. In this article, we’ll explore the ramifications of such equipment-related mishaps, delve into the most common injuries associated with faulty machinery, and shed light on the importance of vigilance in ensuring workplace safety.

The Spectrum of Work Injuries

Work-related injuries can span a wide spectrum, from minor scrapes and bruises to life-altering catastrophes. When it comes to poor equipment, these risks are exacerbated. It’s a chilling reality that the tools and machines we rely on every day to earn our livelihoods can also be the source of our undoing.

Inadequate equipment can trigger a plethora of injuries, ranging from cuts, burns, and sprains to more severe traumas like fractures, amputations, and in some heart-wrenching cases, even fatalities. The risk is not confined to a specific industry or occupation; it’s a concern that affects labourers from construction sites to office spaces.

The Most Common Injury Culprit

Amidst the myriad of injuries that can befall an unsuspecting worker due to poor equipment, one particular injury stands out as the most common – musculoskeletal injuries. These encompass a wide range of conditions that affect the muscles, tendons, ligaments, nerves, and other soft tissues of the body.

Faulty machinery and ill-maintained equipment often necessitate workers to exert extra effort, twist awkwardly, or maintain poor posture, leading to strains, sprains, and chronic pain. Consider a scenario in an office where an employee is provided with a worn-out chair and an outdated computer setup. Over time, they might develop conditions like carpal tunnel syndrome, lower back pain, or even chronic migraines.

In the construction industry, where heavy machinery reigns supreme, musculoskeletal injuries are equally prevalent. For example, an operator forced to use a malfunctioning crane could endure years of agony due to the back strain incurred during a mishap. Such cases are not only painful but can also lead to spiralling medical expenses and extended time off work.

The Silent Culprit: Repetitive Stress Injuries

While musculoskeletal injuries are prevalent, another silent culprit lurks in workplaces – repetitive stress injuries. These injuries develop gradually over time, often unnoticed until the pain becomes unbearable. The repeated, monotonous motions demanded by faulty equipment can wreak havoc on the body.

Let’s take the example of a factory worker tasked with assembling products using a defective machine. The machine requires a particular movement that strains the wrist and forearm, but due to budget constraints, the company delays its repair. Over months, this worker could develop a repetitive stress injury like tendinitis, causing relentless pain and a considerable reduction in productivity.

The same principle applies to office workers who spend hours typing on outdated keyboards. The key action might be stiff or unresponsive, forcing the user to exert excessive force, leading to conditions such as repetitive strain injury (RSI) or carpal tunnel syndrome.

The Gravity of Falls

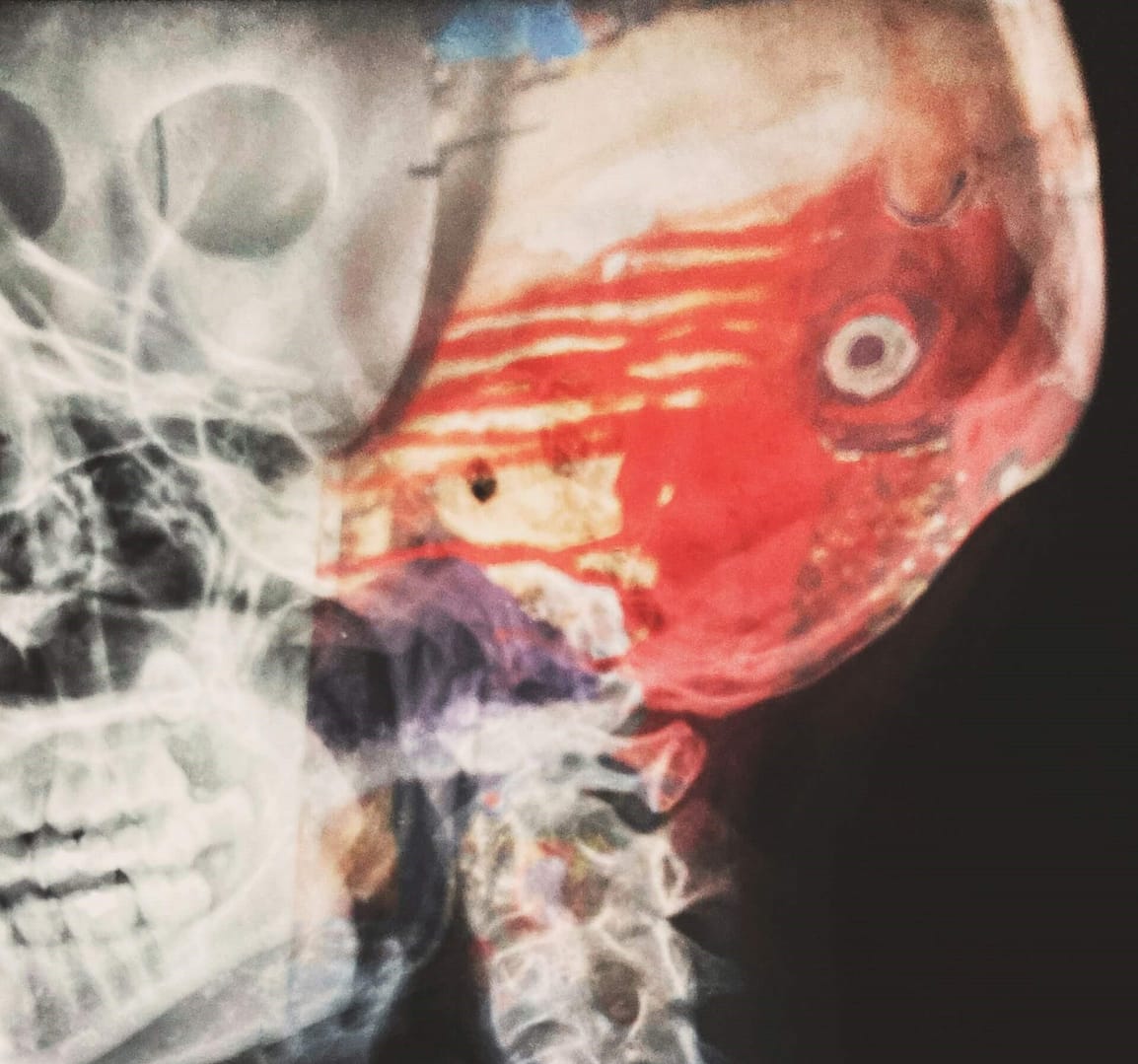

In industries where heavy equipment and machinery are involved, the risk of falling due to poor equipment cannot be overlooked. From construction sites to warehouses, falls from elevated platforms or slippery surfaces due to faulty equipment pose a considerable threat.

Consider a construction worker tasked with climbing scaffolding to perform a critical task. If the scaffold is old and unstable, the worker faces an imminent danger of falling from a significant height. Such falls can result in fractures, head injuries, or worse, fatality.

The same applies to factory workers navigating slick floors due to malfunctioning equipment. One misplaced step can lead to a life-changing injury.

The Burn Risk

In workplaces where heat, electricity, or chemicals are integral, the risk of burn injuries related to poor equipment is a sobering reality. Faulty wiring, malfunctioning heating elements, or inadequate protective gear can all contribute to the likelihood of burns.

Let’s examine a scenario in a small restaurant kitchen. The chef, in a hurry to prepare a meal, uses a stove with a malfunctioning gas valve. When ignited, it results in a sudden, uncontrollable flame that causes severe burns. Burn injuries like these can be excruciating and may necessitate prolonged medical treatment and rehabilitation.

Amputations and Crushing Injuries

In more high-risk work environments such as construction and manufacturing, the peril of amputations and crushing injuries is a haunting presence. This risk stems from the operation of powerful machinery, and when that machinery is defective or poorly maintained, the danger amplifies.

Imagine a scenario on a construction site where a worker is tasked with using a faulty hydraulic press. Due to a sudden malfunction, the press crushes the worker’s hand, leading to a traumatic amputation. The impact of such incidents on the worker’s life, both physically and emotionally, is profound.

The Hidden Costs

Beyond the immediate physical and emotional toll that work injuries involving poor equipment inflict, there are hidden costs that permeate through an organisation and society as a whole.

For businesses, these costs include increased worker compensation claims, potential legal actions, and reduced productivity due to absenteeism and lower morale. Additionally, the tarnished reputation can impact a company’s ability to attract and retain talent.

On a broader scale, the economic burden of work injuries is substantial. In the UK, for instance, the Health and Safety Executive (HSE) reported that workplace injuries and ill health cost the country an estimated £16.2 billion in 2019/2020. This represents a considerable sum, showcasing the far-reaching consequences of inadequate workplace safety.

The Road to Prevention

In the quest to mitigate the perils of work injuries involving poor equipment, the first step is a comprehensive risk assessment. Employers must identify potential hazards and implement measures to eliminate or control them. Regular maintenance and inspections of machinery and equipment are essential to ensuring their functionality and safety.

Employees, too, play a vital role in this endeavour. They should be encouraged to report any faulty equipment and unsafe conditions. Training programs that educate workers about the proper use of equipment and the recognition of potential hazards are also invaluable.

Moreover, governmental agencies and industry standards organisations must continue to develop and enforce regulations that mandate workplace safety and encourage compliance. These regulations serve as a safeguard against lax attitudes towards safety.

Making an Accident at Work Claim with National Claims

As a leading advocate for workplace safety, National Claims is committed to ensuring that those who have suffered work injuries involving poor equipment receive the support and compensation they deserve. Our expert team specialises in guiding you through the complex claims process. With a deep understanding of the legal and financial intricacies involved, we stand by your side throughout the journey.

When you choose National Claims, you’re choosing a dedicated partner who will champion your rights and ensure that the responsible parties are held accountable for their negligence. We understand that the aftermath of a workplace injury can be overwhelming, both physically and emotionally. Our mission is to ease the burden on your shoulders, allowing you to focus on your recovery.

To initiate an accident at work claim, simply reach out to us and provide the details of your case. Our team of legal experts will meticulously assess your situation and advise you on the best course of action. We will navigate the legal complexities, engage with the relevant parties, and strive to secure the compensation you rightfully deserve.

At National Claims, we believe that no one should suffer the consequences of a work injury involving poor equipment without recourse. We are here to ensure that justice prevails and that you can rebuild your life with dignity and financial stability.

Conclusion

Work injuries involving poor equipment cast a long shadow over the modern workforce. From the silent culprits like musculoskeletal and repetitive stress injuries to the more dramatic incidents of falls, burns, amputations, and crushing injuries, the risks are diverse and omnipresent. The consequences of these injuries extend beyond the individual, impacting businesses and society as a whole.

Prevention, therefore, becomes paramount. By fostering a culture of safety, conducting regular inspections, and adhering to stringent regulations, we can work towards reducing the occurrence of work injuries due to poor equipment. Each worker deserves to leave their workplace unscathed, knowing that their safety is a top priority.

For those who have already suffered the consequences of poor equipment at the workplace, National Claims is here to support you in making an accident at work claim. With our experienced team by your side, you can rest assured that your rights will be upheld, and justice will prevail. Your path to recovery and compensation begins with National Claims.

Contact us and get started on your claim for your accident at work.

Click below to see why we are one of the most trusted claims management companies in the UK.

We’re proud of our excellent customer reviews

We thrive on delivering exceptional service and ensuring our clients’ satisfaction. Don’t just take our word for it. Check out some of our independent reviews to see what our clients have to say.

Excellent

This firm is excellent, they sorted out my car pay out and injury claim very fast, they always communicate with you all the time.

My accident case was dealt with confidence and with great result of the outcome, especially James kept me informed all the time.

I was very impressed at the way my inquiry was treated. I was listened to attentively and everything I needed to know was explained to me.